Two BSB 6124XL receiving hoppera have been shipped for customers in Canada.

Each receiving hopper is provided with a fixed kink, which breaks the product flow in the kink and as a result of which a better and more constant dosing to the soil sieve device is realized. A rubber strip under the front of the hopper frame prevents product from getting under the hopper.

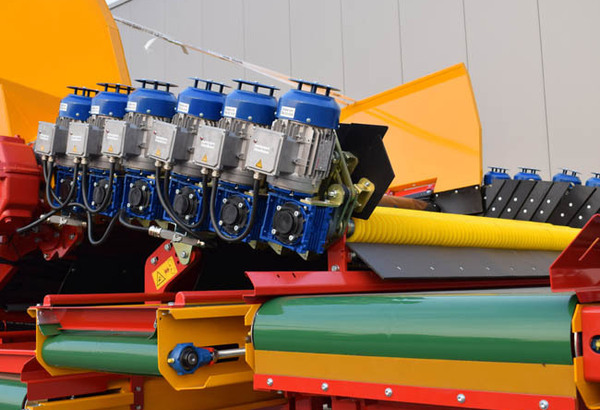

Both the product cleaner and the pre-grader are equipped with PU (plastic) rollers, the speed of which can be continuously changed by means of frequency converters.

The distance between the rollers determines the size of the material falling through, creating a separation between larger and smaller products. The user determines this separation himself.

Performance: